Notre gamme de tours horizontaux 3 axes et axe Y

Pour les pièces complexes nécessitant du fraisage avec axe Y, Tongtai propose les tours horizontaux 3 axes et Axe Y des séries TD et TB.

Accueil » Produits » 3. TOUR » Tour 3 axes et axe Y

Rapide définition d’un tour horizontal ou machine de tournage horizontal

Un tour horizontal est une machine outil dont la broche maintenant la pièce à usiner est à l’horizontale.

Cette broche est mise en rotation et un outil vient usiner la pièce.

Ces outils sont fixés sur une tourelle qui généralement peut stocker de 8 à 16 outils selon la taille de celle-ci (et de la machine).

Il existe des tours de toutes tailles et puissance de broches différentes suivant les besoins de chaque secteur.

- Catégories produits 1. CENTRE D’USINAGE Centre usinage grande vitesse UGV Centre usinage horizontal Centre usinage horizontal 5 axes Centre usinage horizontal et vertical Centre usinage vertical Centre usinage vertical 5 axes Centre usinage vertical ultrasonique 2. CENTRE D’USINAGE A PORTIQUE 5 AXES Centre d’usinage à portique 5 axes à table fixe Centre d’usinage à portique 5 axes à table mobile 3. TOUR Tour 2 axes et 3 axes Tour 3 axes et axe Y Tour Bi-broches Tour vertical 4. MACHINES DE STOCK STOCK : CENTRE D’USINAGE HORIZONTAL STOCK : CENTRE D’USINAGE VERTICAL STOCK : CENTRE D’USINAGE VERTICAL 5 AXES STOCK : TOUR

Tour horizontal 3 axes et axe Y Tongtai Série TB

Pièces jusqu'à Ø450 x Lg610mm

Tour horizontal 3 axes et axe Y Tongtai Série TD

Pièces jusqu'à Ø390xLg560mm

Le tour horizontal 4 axes, une machine de production pour les petites et moyennes séries de pièces complexes

La spécificité du tour 4 axes (3 axes et Axe Y) est que la tourelle peut se déplacer sur l’axe Y, c’est à dire de haut en bas.

Il est donc possible que l’outil soit décalé par rapport à l’axe de rotation de la pièce (au-dessus ou au-dessous) en déplaçant la tourelle selon l’axe Y.

En plus des opération standard de tournage, un tour avec axe Y peut réaliser des pièces de révolution complexes nécessitant des opérations de perçage ou de fraisage.

Tour horizontal 4 axes (X/Y/Z/C) Tongtai Série TD

Parmi la large gamme de machine outils TTGroup France, nous n’avons qu’une série de tour horizontal 4 axes la série TD de Tongtai. Mais celui-ci offre :

- un vrai axe Y et non une combinaison d’axes

- de nombreuses options (broche, broche de reprise, tourelle)

Comme mentionné ci-dessus, l’axe Y de la série TD n’est pas une combinaison d’axes. Cela permet d’avoir une surface X/Z plus grande. L’outil peut atteindre la totalité de cette surface.

Le fait que notre axe Y n’est pas une combinaison d’axe explique la plus grande vitesse en rapide, et permet de fraiser plus vite en avance.

Consulter la page du tour horizontal 4 axes Tongtai Série TD

Que propose TTGroup France?

Tongtai , leader du groupe mais également leader taiwanais de machine outils créé en 1969, a développé une gamme de tours horizontaux.

Honor Seiki est LE spécialiste du tour vertical.

Voir la gamme de tours TTGroup France

NOS AUTRES TOURS

Nos tours 2 AXES OU 3 AXES

Nos tours BI-BROCHES

Nos tours VERTICAUX

A lire aussi.

Si vous désirez compléter votre compréhension sur le fonctionnement et les caractéristiques des tours, vous consulter notre page dédiée à cet effet.

Qu’est-ce qu’un tour machine outil?

3 Axis, 4 Axis & 5 Axis CNC Milling: Best Router?

Written by: Alan Lewis

October 30, 2023

Key Takeaways

- 3 axis CNC machines : The simplest and cheapest type. Good for cutting flat 2D and 2.5D parts.

- 4 axis CNC machines : More flexible and accurate. Can drill on sides and cylindrical surfaces.

- 5 axis CNC machines : The most advanced and expensive type. Can produce complex 3D shapes and angled features.

- Choosing a CNC machine : Depends on your project needs, budget, and desired level of detail.

When it comes to buying a CNC machine , the first and perhaps most important consideration is whether you need a 3 axis CNC router, a 4 axis CNC router, or a 5 axis CNC router?

The decision will tend to be based upon a compromise between the level of detail you’re trying to achieve and the budget you have available .

In this guide, I’ll explain all the differences between 3, 4, and 5 axis CNC machines so you can easily find the right CNC router for you .

In a nutshell:

- 3 axis : Most cost-effective for hobbyists. Good for 2D/2.5D parts.

- 4 axis : More flexible. Can drill on sides/cylindrical surfaces.

- 5 axis : Most precise, but most expensive. Suitable for complex machining and can produce detailed parts.

Let’s start by looking at each option in turn, and then we can compare their use cases side-by-side.

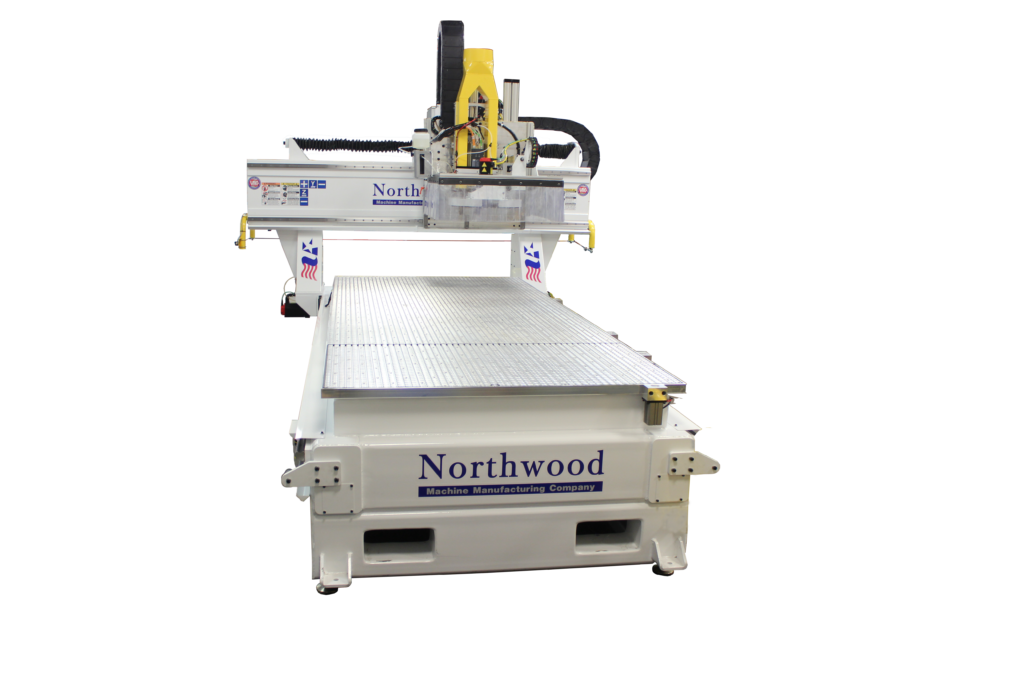

3 Axis CNC Machines

3 axis CNC machines are the most basic out of the three we’re looking at. This technique developed from the process of rotary filling, which uses just the X and Y-axis.

In a 3 axis CNC machine, the three axes are the X-axis, the Y-axis, and the Z-axis. The X-axis moves left to right, the Y-axis moves from front to back, and the Z-axis moves up and down. A 3 axis CNC machine can work on each axis at the same time.

These CNC machines are mostly used for cutting flat 2D and 2.5D parts. It is possible to machine all six sides of a part with a 3 axis CNC machine, but it requires a new fixturing set-up for each side, which is expensive and time consuming.

The workpiece is held flat while the axes move along and cut or mill. 3 axis CNC machining can be used for automatic/interactive operation, drilling holes, cutting sharp edges, and milling slots, and is widely used in the production of mechanical parts.

As 3 axis machines can only move up and down and side to side, the products you can make with them are somewhat limited compared to other machines.

However, complex and practical shapes can still be made with a 3 axis CNC mill, although it’s not well suited for parts that require a lot of depth and detailing. A 3 axis CNC milling machine is better suited to the manufacturing of planar milled profiles, drilling and threaded holes.

So with a 3 axis machine you can create 2D mechanical parts, but you can’t create 3D objects.

While there are industrial 3 axis machines that cost thousands, this type is also the cheapest and most accessible. There are many desktop 3 axis machines easily available to buy on Amazon for a few hundred dollars.

Here are some popular 3 axis CNC routers and mills:

- Vovigo CNC 3018 Pro

- Mostics 2 in 1 CNC 3018 Pro

- Yofuly Upgrade CNC 3018 Pro

- Vevor CNC 3018 Pro

- MakerMade M2 CNC 3 axis

4 Axis CNC Machines

A 4 axis CNC machine features the same three axes as on 3 axis machines, but it also has rotation around the X-axis. This is known as the A-axis. In 4 axis CNC router machining, the workpiece is also usually rotated. This means the machine can act as a milling machine as well as a CNC lathe .

A 4-axis CNC can be arranged in different ways, but they are most commonly set up for vertical machining. This means that the spindle rotates about the Z-axis, while the workpiece is mounted in the X-axis and can therefore rotate in fixture with the A-axis. In a single fixture setup, a 4 axis CNC router can work on four sides of a workpiece.

There are two types of 4 axes CNC machines:

- Index — In index machines, the rotation and cutting are done independently; the workpiece is rotated until in the correct precision and then cutting resumes.

- Continuous — Continuous 4 axis CNC machines are more efficient as they can cut and rotate simultaneously, allowing complex parts like the profile of cam lobes and helixes to be machined.

4 axis machining offers much greater flexibility than 3 axes. For example, it’s ideal for drilling on the side of parts or on cylindrical surfaces – something that isn’t capable with a 3-axis CNC mill.

In a single fixture setup, a 4 axis CNC router can work on four sides of a workpiece. This means it provides a more efficient way of machining parts that would require numerous fixtures if using a 3 axis CNC milling machine, reducing both cost and the time needed to machine the piece.

Also, no fixture changes mean that tighter tolerances are held between features on different sites of the workpiece. 4 axis CNC routers are thus more accurate than 3 axis CNC machines.

A 4 axis CNC mill can also be used to machine angled features — something a 3 axis CNC machine can’t. However, as there is only a single rotational axis per setup, you either need to angle all angled features around the same axis or use multiple fixtures.

Like 3 axis CNC machines, there are both low-cost hobbyist 4 axis CNC routers designed for home use as well as much more expensive industrial machines.

Below are some of the best 4 axis CNC machines:

- Treeback 4 Axis 3040

- Vevor CNC 3040 4 axis

- RanBB 4 axis CNC

- Ten-High 3040 CNC Machine

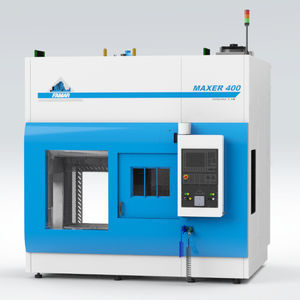

5 Axis CNC Machine

A 5 axis CNC machine offers even greater flexibility and efficiency than 4 axis machines.

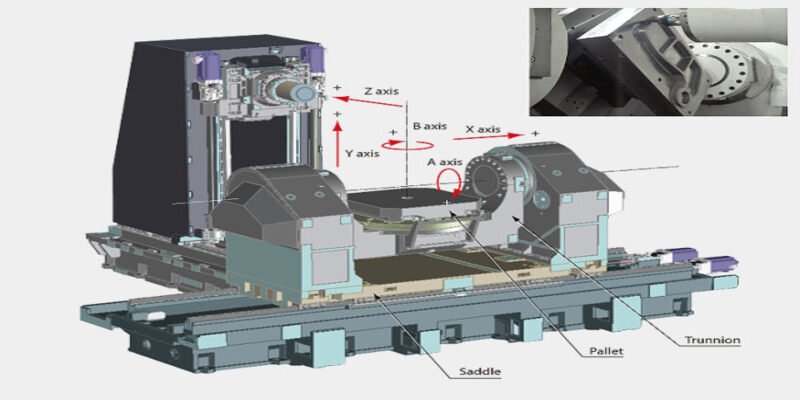

Like in 3 and 4 axis machines, the spindle and cutting tool in 5 axis machines move along the X, Y, and Z-axis. However, in a 5 axis CNC machine, there are rotations around two of the three axes. The rotation around the X-axis is called the A-axis, the rotation around the Y-axis is the B-axis, and the rotation around the Z-axis is the C axis.

5 axis machines can use any two of the rotational axes at the same time, depending on the machine’s configuration. This is either the A-axis and C-axis, or B-axis and C-axis.

In a 5 axis CNC machine, the rotation can occur by either the spindle or the workpiece. This multidimensional movement offers unparalleled accuracy and means that it can perform a wide variety of functions, including milling , turning.

Therefore, with a 5 axis CNC mill you can use a single machine for projects that would otherwise require multiple machines, as it can cut five sides of a part in one fixture. It also offers greater efficiency and improves tool life.

5 axis CNC machines are used in the production of a wide range of precise and very complex parts of things like car molds, artificial bones, military products and aerospace parts.

There are two main types of 5 axis CNC mill: 3+2 machines, and fully continuous machines.

In 3+2 axis machines, two rotational axes operate independently. This means that the workpiece can be rotated to any compound angle for the tool to machine features, but the two-axis rotation can’t be done at the same time as the machining.

In contrast, fully continuous 5 axis machines can rotate two axes simultaneously as the spindle moves the cutting tool along the X, Y and Z coordinates. Both types are able to create highly complex 3D shapes, but fully continuous machines can do so more efficiently.

These machines are the most advanced type of CNC machine and are mostly used in industrial settings. Unlike with the other two types, there aren’t really affordable 5 axis CNC machines for hobbyists.

We’ve listed some of the best 5 axis CNC machine brands below:

- Oracle Precision

- DMG Mori

Difference Between 3 Axis, 4 Axis and 5 Axis CNC Machines

Now we’ve taken a look each type of CNC machine separately, here’s a quick summary of the main difference between each type:

Number & movement of axis

Of course, the number of axes is the most obvious difference, and this influences the directions and movement of the spindle.

A 3 axis CNC machine moves up and down and side to side. A 4 axis CNC router has one rotational axis, while a 5 axis CNC machine has two rotational axes.

Flexibility, accuracy & efficiency

Put simply, the more axes there are, the better the machine in terms of flexibility, accuracy and efficiency.

The rotational axis of a 4 axis CNC machine gives it increased flexibility and makes it suitable for a wide range of applications. The added rotational axis and the faster rotational speed of a 5 axis machine gives even more flexibility.

Applications

Naturally, the differences between these CNC machines mean that they’re best suited for different purposes.

In businesses and industry, 3 axis CNC machines are widely used for making mechanical parts, and they’re also used for a wide range of purposes by hobbyists. A 4 axis CNC mill can do this with the added benefit of being suitable for working with cylindrical surfaces and 3D objects, while a 5 axis machine can carry out much more intricate and complex work.

As they’re the simplest form, 3 axis CNC machines are the cheapest. There are still expensive versions out there, but you can pick up a 3 axis CNC router on Amazon for a few hundred dollars.

A 4 axis CNC router is more expensive, though you can still get good machines for under a thousand dollars. 3 axis and 4 axis CNCs are best for hobbyists and small businesses.

5 axis machines on the other hand are most used in industrial settings and are much more expensive.

What CNC Machine is Best For You?

There are three main considerations you need to make when choosing between a 3, 4, and 5 axis CNC mill — what you’re using the machine for, how much accuracy you need, and your budget.

3 axis machines are best suited for casual hobbyists creating fun CNC projects , or for small home businesses machining of simple parts. They’re cheap, can be easily bought off the internet, and can be easily used to create a wide range of projects.

A 4 axis CNC router is a step up from a 3 axis CNC router in all areas. They can still be bought for a few hundred dollars, but high quality ones are more costly. They offer greater accuracy and flexibility and suit a wider range of applications. They’re best for small and mid-range businesses and serious hobbyists.

While a 5 axis CNC router offers the most advanced machining, their expensive price and more selective availability mean they’re only worth getting if you really need one. That is, if you’re producing complex and intricate parts in an industrial setting.

Conclusion

It’s very important to know the differences between a 3, 4, and 5 axis CNC milling machine before making a purchase.

3 axis machines are the most basic with a spindle that moves up and down from side to side. 4 axis machines add a rotating axis, offering greater efficiency and flexibility. 5 axis CNC machines add a second rotating axis, offering the most accurate, efficient and flexible machining.

What machine is right for you depends on your preferences. 3 axis machines are the cheapest and are best for hobbyists and small businesses. 4 axis machines can be used for more complex projects but are more expensive, while 5 axis machines are mostly used in industrial settings and cost tens of thousands of pounds.

Was this content helpful? Give us your feedback here.

Share this:.

Learn More About CNCSourced

How to Laser Engrave Tumblers in Lightburn

11 Best CNC Software 2024 (Router Controller, CAD-CAM)

9 Great CAD CAM Software (For All Uses) 2024

The BEST Black Friday CNC Router/Machine Deals 2023

10 Essential CNC Router Accessories in 2024

10 Industries CNC Routers Are Used In

4 Best Laser Cutters For Acrylic in 2024 (All Prices)

4 Best Wood Laser Cutters & Engravers For Crafts 2024

4 Best Laser Engravers For Glass Etching 2024

The BEST Black Friday Laser Cutter & Engraver Deals 2023

8 Best Nesting Software For Laser Cutters (Free & Paid)

Raster vs Vector Engraving: When To Use Each Type

40+ CNC Industry Stats & Facts (2024)

How Hot Is A Laser Cutter? Simply Explained

xTool S1 Review: Best Professional Diode Laser Cutter

xTool F1 Review: the BEST Laser For Craft & Trade Shows

xTool P2 FULL Review: It’s Better Than Glowforge & Gweike Cloud

Snapmaker 2.0 Review – Laser & CNC Toolhead Test

Leave a comment cancel reply.

Save my name, email, and website in this browser for the next time I comment.

The most informative CNC site on the web

[email protected]

CNC Routers CNC Machining Laser Cutters Software Rankings Reviews Comparisons Guides

Most Popular

Best Laser Cutters Best CNC Routers Best Cheap Laser Engravers Glowforge Alternatives Best Laser Engravers For Metal Best CO2 Laser Cutters Best CNC Mills Best CNC Machines For Small Business Best DIY CNC Routers Best 4x8 CNC Routers

Useful Links

About us About the team How we do our reviews Careers Contact Us

Sign up to our newsletter

Privacy policy

Terms and conditions

Affiliate disclaimer

Cookie policy

GDPR policy

Modern slavery statement

Accessibility

Complaints policy

Code of ethics

Editorial policy

CNC LATHES & TURNING CENTERS

3-Axis CNC Lathes

3-Axis CNC Lathes (or Turning Centers) w/ Live Tools

Enable the workpiece to be stationary or slowly turned (or jogged; sometimes referred to as the C-axis (or contouring spindle) while a rotating cutting tool (or live tool) moves across the X & Z axes to mill or drill features in the work piece that are not concentric to the work piece. Terminology varies throughout the industry but sometimes the 3rd axis can be another linear axis, called a Y-axis. Find out more about Y-axis in our Multi Axis CNC Lathes section.

Why Choose Hillary Machinery for New 3-Axis CNC Lathes (Live Tools)

Choosing the right company for your 3-Axis CNC Lathes (Live Tools) Equipment purchase is critical. Look no further than Hillary Machinery. We are a trusted supplier recognized for offering top-notch machinery and a varied selection of products to cater to your operation's needs. Our focus on ensuring you choose what best fits your specific application truly sets us apart.

Brands We Offer

- HYUNDAI WIA CNC MACHINE TOOLS

We proudly supply equipment from world-leading brands like HYUNDAI WIA CNC MACHINE TOOLS and DMC, ensuring you benefit from the latest and highly efficient technology available.

Industries That Benefit from 3-Axis CNC Lathes (Live Tools)

3-Axis CNC Lathes (Live Tools) is widely utilized in various industries including aerospace, automotive, medical, and mold-making among others. Its inherent versatility and precision have revolutionized manufacturing processes, enhancing productivity and quality standards.

Unique Selling Points and History of 3-Axis CNC Lathes (Live Tools)

The 3-Axis CNC Lathes (Live Tools) offers multiple benefits such as faster production, exceptional tolerance levels, and the ability to create complex designs with sublime accuracy. Since the advent of CNC technology in the mid-20th century, the machinery has undergone continuous development. Today, the inclusion of live tooling capabilities has further enhanced the usage and applications of these lathes, making them a highly coveted asset in numerous manufacturing setups.

Brands within 3-Axis CNC Lathes (Live Tools)

- YAMA SEIKI CNC MACHINE TOOLS

Previously sold within 3-Axis CNC Lathes (Live Tools)

- Sold 3-Axis CNC Lathes (Live Tools) Listings

Exploring 3-Axis CNC Machining: Capabilities And Limitations

Table of Contents

The Basics of 3-Axis CNC Machining

Applications of 3-axis cnc machining, key takeaways, what are the capabilities of 3-axis cnc machining, what are the limitations of 3-axis cnc machining, how does 3-axis cnc machining compare to other cnc machining techniques, what industries benefit from 3-axis cnc machining, what factors should be considered when choosing a 3-axis cnc machine, final thoughts.

Welcome to the fascinating world of 3-Axis CNC machining. In this article, we will delve into the capabilities and limitations of this advanced manufacturing technique. Whether you’re a seasoned engineer or simply curious about the inner workings of CNC machines, we’ve got you covered. So, grab a cup of coffee, sit back, and let’s explore the exciting realm of 3-Axis CNC machining together!

When it comes to CNC machining, the term “3-Axis” refers to the three directions in which the machine can move: X, Y, and Z. This means that the machine can move left or right (X-axis), forward or backward (Y-axis), and up or down (Z-axis). By controlling the movement of the cutting tool along these axes, intricate and precise designs can be achieved. From creating complex parts for the aerospace industry to crafting intricate molds for the automotive sector, 3-Axis CNC machining has revolutionized the way we manufacture products.

However, like any technology, 3-Axis CNC machining also has its limitations. One of the main constraints is the inability to reach certain angles or contours due to the fixed movement along the three axes. This means that intricate designs with complex curves may not be achievable with a 3-Axis machine alone. Additionally, the process can be time-consuming for intricate designs, as the machine needs to make multiple passes to achieve the desired result. Nonetheless, with careful planning and skilled programming, these limitations can often be overcome, making 3-Axis CNC machining a versatile and powerful tool in the world of manufacturing. So, let’s dive deeper and uncover the incredible potential of this cutting-edge technology.

Exploring 3-Axis CNC Machining: Capabilities and Limitations

CNC machining has revolutionized the manufacturing industry, allowing for precise and efficient production of various parts and components. Among the different types of CNC machines, 3-axis machining is one of the most commonly used. In this article, we will delve into the capabilities and limitations of 3-axis CNC machining, exploring its applications and advantages.

3-axis CNC machining refers to the movement of the cutting tool along three axes: X, Y, and Z. The X-axis represents the horizontal movement, the Y-axis represents the vertical movement, and the Z-axis represents the depth or thickness of the material being machined. This type of machining is typically used for simpler and less complex parts that do not require intricate and precise movements.

In 3-axis CNC machining, the cutting tool is fixed to a spindle that moves along the X, Y, and Z axes based on the instructions programmed into the computer software. This allows for the production of parts with relatively simple geometries, such as flat surfaces, holes, and slots. The simplicity of 3-axis machining makes it a cost-effective solution for many manufacturing applications.

Capabilities of 3-Axis CNC Machining

1. versatility.

One of the main advantages of 3-axis CNC machining is its versatility. It can be used to produce parts and components for a wide range of industries, including automotive, aerospace, electronics, and more. Whether it’s creating prototypes, producing small batches, or manufacturing larger quantities, 3-axis machining can handle various production requirements.

2. Cost-Effectiveness

Another benefit of 3-axis CNC machining is its cost-effectiveness. Compared to more complex machining processes like 5-axis or multi-axis machining, 3-axis machining requires less advanced equipment and programming, resulting in lower production costs. This makes it an attractive option for businesses looking to optimize their manufacturing processes without breaking the bank.

Limitations of 3-Axis CNC Machining

1. limited complexity.

While 3-axis CNC machining offers versatility, its main limitation lies in its ability to produce complex parts. The movement along only three axes restricts the machine’s ability to create intricate geometries and features. Parts with undercuts, curved surfaces, or complex contours may require additional operations or alternative machining methods.

2. Reduced Precision

Compared to more advanced machining techniques, 3-axis CNC machining may have limitations in terms of precision. The fixed tool orientation and limited movement can result in less precise cuts and finishes, especially for parts that require high accuracy. For applications that demand tight tolerances and intricate details, alternative machining methods may be necessary.

In summary, 3-axis CNC machining offers versatility and cost-effectiveness, making it suitable for a wide range of manufacturing applications. However, its limitations in terms of complexity and precision should be considered when determining the appropriate machining method for specific parts. By understanding the capabilities and limitations of 3-axis CNC machining, manufacturers can make informed decisions and optimize their production processes accordingly.

1. Prototyping

When developing new products or refining existing designs, prototyping is a crucial step in the manufacturing process. 3-axis CNC machining is often used for prototyping due to its simplicity, speed, and cost-effectiveness. It allows manufacturers to quickly produce prototypes and make necessary adjustments before moving forward with full-scale production.

2. Production of Flat Parts

3-axis CNC machining excels in producing flat parts with simple geometries, such as plates, brackets, and panels. The machine’s ability to move along the X, Y, and Z axes allows for efficient cutting and shaping of flat surfaces. This makes it an ideal choice for industries that require large quantities of flat parts, such as construction, signage, and automotive.

3. Hole Drilling and Tapping

Another common application of 3-axis CNC machining is hole drilling and tapping. The machine can accurately drill holes of various sizes and depths, as well as tap threads for screws and bolts. This makes it a valuable tool in industries that rely on precise hole patterns, such as electronics, furniture, and machinery manufacturing.

4. Engraving and Marking

3-axis CNC machines can also be used for engraving and marking purposes. By utilizing specialized cutting tools and programming, manufacturers can create intricate designs, logos, and serial numbers on various materials. This is particularly useful in industries that require product branding, customization, or identification, such as jewelry, signage, and promotional item production.

5. Production of Simple Molds

For industries that require simple molds, 3-axis CNC machining can be a cost-effective solution. The machine can create molds for casting or forming processes, allowing manufacturers to produce multiple identical parts. While complex molds may require more advanced machining techniques, 3-axis machining serves as a viable option for simpler mold designs.

In conclusion, 3-axis CNC machining offers a versatile and cost-effective solution for a wide range of manufacturing applications. Its capabilities in prototyping, producing flat parts, hole drilling, engraving, and simple mold production make it a valuable tool in many industries. However, its limitations in complex part production and precision should be considered when determining the appropriate machining method. By understanding the capabilities and limitations of 3-axis CNC machining, manufacturers can make informed decisions and optimize their production processes for maximum efficiency and cost-effectiveness.

- 3-axis CNC machining is a technology used to create precise and complex parts.

- It allows for machining in three directions: X, Y, and Z axes.

- This technology is widely used in industries like aerospace, automotive, and manufacturing.

- With 3-axis CNC machining, you can create intricate designs and prototypes.

- However, it has limitations in terms of the complexity and size of the parts it can produce.

Frequently Asked Questions

3-axis CNC machining refers to the ability of a CNC machine to move along three axes: X, Y, and Z. This allows for the creation of complex shapes and intricate designs with high precision. The capabilities of 3-axis CNC machining are vast and include:

1. Versatility: 3-axis CNC machines can handle a wide range of materials, including metals, plastics, and wood. They can be used for various applications such as prototyping, production machining, and engraving.

2. Precision: With the ability to move along three axes, 3-axis CNC machines can achieve high levels of accuracy and repeatability. This makes them ideal for producing parts with tight tolerances.

3. Efficiency: 3-axis CNC machining can significantly reduce manufacturing time and costs. The automation and computer-controlled precision of these machines allow for faster production and minimal material waste.

While 3-axis CNC machining offers numerous advantages, it also has certain limitations that need to be considered:

1. Limited complexity: 3-axis CNC machines are unable to produce highly complex geometries that require simultaneous movement along multiple axes. This can be a limitation when working on intricate designs or parts with intricate features.

2. Surface quality: Due to the nature of 3-axis machining, there might be limitations in achieving smooth surface finishes, especially on curved or contoured surfaces. Additional finishing processes may be required to achieve the desired surface quality.

3. Tool accessibility: The tooling used in 3-axis CNC machining may have limited access to certain areas of a part, particularly undercuts or hard-to-reach areas. This can pose challenges when machining complex shapes or features.

3-axis CNC machining is a popular choice for many applications, but it’s important to understand how it compares to other CNC machining techniques:

1. 3-axis vs. 4-axis: 3-axis CNC machining is limited to three axes of movement, while 4-axis machining adds an additional rotary axis. This allows for more complex geometries and the ability to machine features on multiple sides of a part without repositioning.

2. 3-axis vs. 5-axis: 3-axis CNC machining is further limited compared to 5-axis machining, which adds two additional rotary axes. 5-axis machines offer even greater flexibility and the ability to machine complex shapes from multiple angles, reducing the need for multiple setups.

3. 3-axis vs. multi-axis: Multi-axis CNC machining refers to machines with more than three axes. These machines can provide even greater capabilities and versatility, allowing for the production of highly complex parts with intricate features.

3-axis CNC machining finds applications in various industries due to its versatility and precision:

1. Automotive: 3-axis CNC machines are used to produce parts for automotive components, including engine components, interior trim, and exterior body panels.

2. Aerospace: The aerospace industry relies on 3-axis CNC machining for the production of aircraft components, such as turbine blades, wing sections, and structural parts.

3. Electronics: 3-axis CNC machines are used in the electronics industry to manufacture electronic enclosures, circuit boards, and other components.

4. Medical: Medical devices and implants often require complex geometry and precise machining, making 3-axis CNC machining an essential process in the medical industry.

When selecting a 3-axis CNC machine, several factors should be taken into account:

1. Size and capacity: Consider the size and weight of the parts you intend to machine and ensure that the machine can accommodate them. Also, consider the working area and the maximum travel distances of the machine.

2. Accuracy and precision: Evaluate the machine’s specifications in terms of positioning accuracy and repeatability. This is crucial for achieving the desired level of precision in your machining operations.

3. Software compatibility: Ensure that the machine’s control software is compatible with your design and programming software. This will streamline the workflow and ensure efficient communication between the software and machine.

4. Support and service: Research the reputation of the manufacturer and their after-sales support. It’s important to have access to technical support and spare parts when needed.

5. Budget: Consider your budget and compare the features and capabilities offered by different machines. Balance your requirements with the cost to find the best fit for your needs.

After exploring the capabilities and limitations of 3-Axis CNC machining, it’s clear that this technology offers immense potential for a wide range of industries. The precision and efficiency of 3-Axis CNC machines make them a valuable tool for manufacturing intricate and complex parts. From automotive to aerospace, these machines have revolutionized the way we produce goods.

However, it’s important to acknowledge the limitations of 3-Axis CNC machining. While it excels at creating parts with relatively simple geometries, it may struggle with complex shapes that require more axes of movement. Additionally, the size of the machine’s work envelope can also pose a constraint on the size of the parts that can be produced.

In conclusion, 3-Axis CNC machining is a powerful tool that has transformed the manufacturing industry. Its capabilities in terms of precision and efficiency make it a sought-after technology. By understanding its limitations and working within them, manufacturers can harness the full potential of 3-Axis CNC machining to create high-quality products that meet the demands of the modern market. So, embrace this technology and unlock a world of possibilities for your business.

Request a quote today!

Project Description (Please include material, quantity & finishing)

Upload 2D/3D Drawings

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

Here Are More Worth Reading

Thread Tapping Tools: Techniques And Tips For Successful Tapping

Alloy Steel Vs. Carbon Steel: Comparing Strength And Properties

Plastic Fabrication: Creating Customized Plastic Components

Leave a comment cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Mastering the Art of 3-Axis Machining for Complex Geometries

1. the core fundamentals of precision 3-axis cnc machining, 2. industry-specific applications of 3-axis machining, 3. mastering complex geometries with 3-axis machining, 4. critical considerations for effective custom 3-axis machining, 5. understanding the limitations and overcoming challenges, 6. innovating with advanced custom 3-axis machining techniques, 7. 3-axis vs. 5-axis machining, 8. conclusion, related posts, your guide to surface treatment solutions for aluminum parts, mastering stainless steel cnc machining: the ultimate guide, what types of materials can be cnc machined, top 10 metal surface finishing types you must know.

3-axis CNC machining stands as a cornerstone in modern manufacturing, where cutting tools move along three axes—X, Y, and Z—to shape materials. This process is the backbone for creating a myriad of precision components across diverse industries.

Recognizing the importance of precision and customization, many sectors like aerospace, medical, and automotive demand accuracy in crafting their unique parts. Their needs underscore the vital role that expertly executed 3-axis machining plays.

In this article, we will master techniques that optimize 3-axis machining. We will uncover how to achieve intricate designs with the utmost precision.

Exploring the 3-Axis Machining Process:

The 3-axis machining process manipulates both the piece of material and the cutting tool in three directions, known as X, Y, and Z axes. This enables much higher precision than 2-axis machining, which can only move on two planes. A 3-axis setup can approach apart from both horizontal directions and vertically.

This ability to cut in multiple directions allows machinists to do complicated cuts and accurately create detailed features. The complex movement combined with high-tech control makes 3-axis methods flexible and essential for precise work.

Enhancing Accuracy with 3-Axis CNC Milling:

In precision 3-axis CNC milling, getting things exactly right is crucial—it's the difference between an outstanding product and one that doesn't meet standards. Custom CNC milling allows producers to adjust their equipment to make parts with incredible precision, sometimes within microns.

Automated controls reduce the chance of human mistakes, ensuring consistency across many items made in one batch. Also, sensors always check how well everything works during cutting operations. They make immediate adjustments when needed to maintain constant accuracy. This combination of automated supervision and ongoing monitoring is critical to reaching top precision for every piece that's made.

Essential CNC Machines in Custom 3-Axis Machining Solutions:

- Vertical machining centers: Renowned for their versatility and widely used in custom jobs.

- Horizontal milling machines: Preferred when large amounts of material need removal.

- Universal machines: Offer flexibility with a swiveling spindle that extends operational capabilities.

These machines form the backbone of any workshop committed to delivering high-quality components through custom CNC milling solutions.

Preferred Materials for 3-Axis Machining:

In 3-axis machining centers, material selection is pivotal, balancing machinability, strength, and cost.

- Aluminum: Lightweight, easy to machine, ideal for high-speed operations. They are commonly used in the automotive and aerospace industries.

- Stainless Steel: Known for its strength and corrosion resistance, it is used in demanding environments like medical devices and food processing equipment.

- Plastics (e.g., Acrylic, Nylon): Versatile, easy to machine with a good finish. They are used in consumer products, prototypes, and non-stress applications.

- Composites (e.g., Carbon Fiber Reinforced Polymers): High strength-to-weight ratio, specialized tooling required and used in aerospace, automotive, and sports equipment.

- Engineering Materials (e.g., Titanium, Inconel): Exceptional properties for aerospace and medical applications. It is challenging to machine but offers superior strength and temperature resistance.

Selecting the suitable material is crucial, affecting everything from cut quality to tool lifespan within operations carried out by a precision custom or standard 3-axis machining center.

Custom 3-axis CNC milling solves many industries because it can precisely make difficult shapes.

- Aerospace: In aerospace, companies use custom 3-axis machining to create lightweight parts that can withstand harsh environments. Some commonly produced parts are airframe structures, airfoils, and turbine parts.

- Automotive: The automobile industry also uses the flexibility of 3-axis machines for a variety of purposes, from complex engine components to smooth body panels.

- Healthcare: In healthcare, where accuracy matters a lot, 3-axis CNC mills produce surgical devices and implants with smooth surfaces to meet high health standards.

- Electronics: In electronics manufacturing, where parts are often tiny and complex, these machines play a crucial role by cutting and drilling with great precision.

High-Precision Products Achieved Through 3-Axis Machining:

The products resulting from 3-axis machining boast unparalleled precision. Aerospace companies use this technology to craft airframe structures that adhere to rigorous safety regulations. In automotive, gearbox parts and suspension systems produced using custom CNC milling ensure reliability and longevity on the road.

For medical devices like orthopedic implants made from biocompatible materials, 3-axis CNC milling yields tolerances tight enough to fit within human anatomy perfectly. Electronic components such as connectors and enclosures also benefit from this method's fine resolution capabilities—ensuring seamless integration into a wide array of devices.

In every instance, custom 3-axis machining solutions provide industrial players with the tools they need for success—a testament to the technology's adaptability, which suits various requirements across different market landscapes.

The effectiveness of 3-axis machining in creating detailed geometries lies in strategic approaches. Advanced planning using state-of-the-art CAM software sets the stage. This software plots specific paths for cutting tools, enabling the formation of intricate designs that are otherwise impossible to achieve manually.

Furthermore, tool geometry selection is paramount. Tools must be chosen not merely for their ability to cut but also for their compatibility with the material and complexity of the part. This synergy further refines a precision manufacturing process, facilitating impeccable final products.

Consideration of several factors is imperative when deploying custom 3-axis machining solutions.

- One is material selection–knowing whether a material can withstand intensive milling without warping or losing its desired properties is crucial in curating an effective strategy.

- Machine calibration at a 3-axis machining center comes next, ensuring that devices operate within their tightest tolerances and with advanced accuracy.

- Additionally, addressing work-holding challenges wisely can drastically affect both quality and efficiency, particularly when dealing with complex shapes that might necessitate unconventional fixturing methods.

- Workflow optimization also plays a central role–managing the sequence of operations to minimize non-cutting time.

Businesses harness robust custom solutions by combining these data-driven strategies with hands-on knowledge from experienced machinists.

Limitations:

Although 3-axis machining provides a robust foundation for custom CNC milling, it's essential to thoroughly recognize its limitations to harness its capabilities. The three linear axes offer excellent coverage for a multitude of shapes and sizes. Still, the configuration has constraints when dealing with complex geometries that require undercutting or machining from multiple angles.

These inherent limitations mean that sometimes jobs may need repositioning or additional setups, which could potentially introduce errors and affect the overall precision of the final product. However, experienced machinists anticipate such issues and plan jobs meticulously to ensure flawless execution.

Best Practices to Overcome Custom 3-Axis Machining Challenges:

Overcoming the challenges in precision 3-axis CNC machining involves instituting a series of best practices that enhance performance and mitigate potential downsides.

- Firstly, maintaining equipment rigorously is key; proper calibration and alignment are imperatives that preserve the accuracy capabilities of these sophisticated machines.

- Employing simulation software stands out as another critical practice. It acts as an effective mechanism for preempting errors by providing a clear view of possible outcomes before machining starts—a proactive approach to troubleshooting.

- Moreover, keeping abreast with cutting-edge tool technology can overcome material-specific issues; modern coatings and tool materials cater specifically to unique machining demands. These specialized tools can extend operation life while boosting productivity within 3 axis configurations.

- Collaborative approaches also play a crucial role—where skilled engineers work closely together during programming stages—to optimize tool paths effectively and refine workflows. Such collaboration ensures cohesive operations where complexities are confronted and conquered strategically.

- Taking advantage of advanced fixtures offers additional support by enabling accurate part location and rigidity during the intensive cutting processes—a must for achieving high-tolerance components under challenging conditions.

- Lastly, investing in workforce skill development is integral. Machinists who undergo continued training often bring more creativity and problem-solving abilities into play, factors which directly improve outcomes in precision 3-axis CNC machining.

In each challenge resides an opportunity to analyze, innovate, and elevate practices within 3-axis machining processes, further enhancing their capability to produce precision parts that meet today's ever-increasing industry standards.

The world of 3-axis machining is constantly evolving, driven by the pursuit of greater accuracy and efficiency. Among the advancements pushing this field forward are high-speed machining techniques that increase cutter speeds and feed rates without compromising precision. These allow machinists to reduce cycle times significantly while maintaining output quality.

As technologies develop, dynamic milling strategies enable deeper cuts at a higher feed rate, even on complex paths. This approach maximizes material removal rates, translating into time savings and reduced tool wear—a testament to its effectiveness in 3-axis machining.

Enhancing Capabilities with CAD/CAM Software:

State-of-the-art CAD/CAM software has provided an additional edge to modern 3-axis machining centers. This powerful software supports sophisticated design and manufacturing processes, permitting detailed simulations which can predict potential complications before actual production begins.

Toolpath optimization algorithms within these applications generate efficient routes for tools to follow, reducing unnecessary machine movement and extending tool life. Thanks to such innovative features, the capabilities of 3-axis machining are witnessing unprecedented expansion.

Integrating next-generation features such as adaptive clearing keeps machines only safely cutting the amount their tools and spindles can handle. This reduces the stress of machinery components, contributing to longer machine life spans—the hallmark of premium 3-axis CNC setups.

What’s More?

Advancements in programming enable smoother transitions between different feature depths by adjusting cutting parameters 'on-the-fly.' This fine-tuning minimizes jolts, or sudden direction changes that could compromise finished parts' durability or aesthetics during 3-axis operations.

Automation technologies also intersect with three-axis systems, adding capabilities like automated part loading and unlaying—elements that further enhance productivity. With automation integration, facilities having robust 3-axis equipment can now enjoy extended unattended operations or lights-out manufacturing.

Lastly, IoT connectivity opens doors for 'smart manufacturing' where 3-axis machines communicate with other factory systems for seamless workflows (also), facilitating predictive maintenance regimes based on real-time operational data so downtime due to unexpected breakdowns can be minimized if not entirely avoided.

By embracing these advanced custom techniques within three-axis CNC machining, manufacturers are refining their ability to produce parts more quickly and economically without sacrificing quality—one dynamic innovation at a time.

The choice between 3-axis machining and 5-axis systems hinges on several factors influencing precision manufacturing. While both can deliver high-quality products, their flexibility and complexity management are the main difference. Five-axis machines come with additional rotational axes (A and B), allowing for more intricate designs with fewer setups.

Whereas 3-axis machining is well-suited for parts that don't require complex angles or undercuts, 5-axis machines excel at creating sophisticated shapes with deeper cavities or complex profiles. When deciding between both, manufacturers consider the geometry of the part, the tolerances required, and ultimately, the cost-effectiveness of using one system over the other.

Which Option is Budget-Friendly?

When it comes to balancing budget constraints with production needs, 3-axis machining often emerges as a more cost-effective choice. It's typically less expensive in terms of initial investment and maintenance costs compared to its five-axis counterparts.

However, for highly specialized applications with extreme geometries, investing in a five-axis machine might reduce overall costs by minimizing the need for multiple setups and separate finishing processes. In essence, picking between these two routes in precision manufacturing relies upon assessing immediate needs against long-term value creation.

3-axis machining has established itself as an essential process in modern manufacturing, offering custom solutions and high-precision products across a multitude of industries. Here's a quick recap of the key takeaways:

- 3-axis machining utilizes X, Y, and Z axes for versatile cutting capabilities.

- Precision manufacturing with 3-axis CNC milling is fundamental to industry-specific applications.

- Advances in CAD/CAM software have significantly enhanced 3-axis machining

As 3-axis technology continues to evolve, its future looks geared toward integrating even more automation and intuitive software—poised for greater efficiency and precision. For comprehensive services encapsulating these methodologies, Rally Precision stands ready to meet your needs. Contact us for expert 3-axis machining services tailored to your project requirements.

Frequently Asked Questions:

1. what materials can be machined using 3-axis cnc milling.

Three-axis CNC milling machines are versatile, capable of machining a wide range of materials. Metals like aluminum, brass, copper, steel, and titanium are commonly processed due to their excellent machinability and industrial applications. Plastics such as ABS, polycarbonate, PEEK, and PVC are also popular choices, especially for prototypes or components requiring lower weight and corrosion resistance.

2. What are the G-codes and M-codes?

G-codes and M-codes are programming languages used in CNC (Computer Numerical Control) machining to control machine tools. G-codes are primarily used for specifying geometry-related instructions like movement, speed, and feed rate. They instruct the machine on how to move, turn, and shape the material. M-codes, on the other hand, handle machine functions such as turning the spindle on or off, changing tools, or controlling coolant. Together, these codes form the backbone of CNC programming, enabling precise control over the machining process.

3. From where can I get 3-axis CNC milling services in China?

You'll find numerous suppliers online that offer 3-axis CNC milling services in China. But don't just trust online reviews, as they can be paid for or faked. Always ensure they have a good track record for quality and reliability before committing.

Get A Quick Quote For Your New Project !

Our expert team and advanced manufacturing capabilities are ready to support your project from prototype to mass production. Contact us now to get started!

By email or online form

Send your 2d/3d drawings.

Sep 13 2021

Mar 21 2024

Language English French Spanish German Italian Japanese Dutch Polish Ukrainian Turkish Romanian Portuguese Russian Arabic Vietnamese China

What is a 3-axis CNC machining and how does it work?

- 3 axis cnc machining

If you are involved in manufacturing or engineering, you may have heard the term “CNC machining” thrown around. But what is 3-axis CNC machining, and how does it work? In this article, we will explore the basics of 3-axis CNC machining, including its components, operation, and applications. We will also discuss the advantages and limitations of this manufacturing process, its difference from 4-axis milling and 5-axis milling, as well as tips for finding a high-precision 3-axis CNC machining service provider. Whether you are new to CNC machining or looking to expand your knowledge, read on to learn more.

What is 3-axis CNC machining

3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes. The X-axis and Y-axis control the horizontal movement of the tool, while the Z-axis controls the vertical movement.

In 3-axis CNC machining, the cutting tool remains perpendicular to the surface of the workpiece throughout the process. This limits the complexity of the shapes that can be produced but allows for relatively fast and straightforward manufacturing of simple parts with straight sharp edges and flat surfaces.

3-axis CNC machining is commonly used in a variety of industries, including aerospace, automotive, electronics, and medical devices. It is ideal for producing simple parts such as brackets, panels, and housings, and is often used for prototyping and small-scale production runs.

Components of a 3-axis CNC milling machine

A 3-axis CNC milling machine consists of several key components that work together to create precise and accurate parts and components. Some of the main components of a 3-axis CNC milling machine include:

1. Machine frame: This is the backbone of the machine that provides the necessary stability and rigidity for the machining process.

2. Spindle: The spindle is the motorized tool that rotates the cutting tool or drill bit. It is responsible for creating the cutting action needed to shape the material being machined.

3. Worktable: The worktable is the surface on which the material being machined is placed. It can move along the X and Y axes to allow for precise positioning of the material.

4. CNC controller: The CNC controller is the brain of the machine, responsible for interpreting the CAD/CAM software and controlling the movement of the machine along the X, Y, and Z axis.

5. Cutting tools: Cutting tools are the various tools used in the machining process, such as end mills, drills, and reamers. These tools are selected based on the specific material being machined and the desired shape or finish.

Together, these mechanical components work in sync to produce highly precise and accurate parts and components, making 3-axis CNC machining a critical technology in the manufacturing industry.

How 3-axis CNC machining works

3-axis CNC machining involves several steps, from the design of the part in CAD software to the actual machining process. Here’s how it works:

1. Computer-aided design (CAD) and computer-aided manufacturing (CAM): The first step in 3-axis CNC machining is designing the part in CAD software. Once the design is complete, it is converted to a format that can be read by the CAM software.

2. Generating G-code: The CAM software generates G-code, which is a series of commands that the CNC machine can understand. The G-code contains information on the tool path, speed, and depth of cut.

3. Loading the G-code into the CNC controller: The G-code is loaded into the CNC controller, which is responsible for interpreting the code and controlling the movement of the machine.

4. Setting up the machine: The workpiece is loaded onto the worktable and secured in place. The cutting tool is also installed and secured in the spindle.

5. Executing the program: Once the machine is set up, the program is executed. The CNC controller reads the G-code and moves the machine along the X, Y, and Z axis to create the desired shape.

6. Post-processing and inspection: After the machining process is complete, the part is inspected for accuracy, and any necessary post-processing steps are performed.

Applications of 3-axis CNC machining

3-axis CNC milling is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The tool moves in three axes (X, Y, and Z) to create precise cuts and shapes. Here are some common applications of 3-axis CNC milling:

1. Prototyping: 3-axis CNC milling is often used to create prototypes of new products. It can produce precise and accurate parts quickly, allowing designers to test and refine their ideas before moving into production.

2. Aerospace and Defense: 3-axis CNC milling is used extensively in the aerospace and defense industries to create complex parts for aircraft, missiles, and other vehicles. These parts must meet strict tolerances and quality standards, and 3-axis CNC milling is ideal for producing them.

3. Automotive: The automotive industry uses 3-axis CNC milling to create parts for engines, transmissions, suspension systems, and more. This process allows for high levels of precision and accuracy, which is essential in automotive manufacturing.

4. Medical Devices: The medical industry uses 3-axis CNC milling to create implants, prosthetics, and other medical devices. These parts must be highly precise and customized to fit the needs of individual patients.

5. Jewelry: 3-axis CNC milling is used in the jewelry industry to create intricate designs and patterns on metal, such as rings, pendants, and bracelets.

6. Electronics: The electronics industry uses 3-axis CNC milling to create printed circuit boards (PCBs) and other components. This process allows for the precise and accurate manufacturing of small, intricate parts.

7. Mold Making: 3-axis CNC milling is used in mold making to create molds for plastic injection molding, die casting, and other manufacturing processes. This allows for the mass production of parts with greater accuracy and consistency.

Advantages of 3-axis CNC machining

3-axis CNC machining offers several advantages over traditional machining methods. Some of the key advantages include:

1. High accuracy and repeatability: 3-axis CNC milling machines can produce highly accurate parts with tight tolerances, which ensures consistency and repeatability in production runs.

2. High production speed: CNC machines can operate continuously without the need for manual intervention, which means they can produce parts at a much faster rate than traditional machining methods.

3. Ability to machine complex shapes: CNC machines can machine complex shapes with ease, including parts with intricate geometries and curved surfaces.

4. Reduced labor costs: CNC machines require minimal manual labor, which can significantly reduce labor costs and increase efficiency in production processes.

In general, 3-axis CNC milling is a versatile and efficient process that offers numerous benefits over traditional machining methods. It has become a widely used technology in various industries, including automotive, aerospace, medical, and electronics, among others.

Limitations of 3-axis CNC machining

Despite the numerous advantages of 3-axis CNC machining, there are also some limitations to this technology. Some of the key limitations include:

1. Limited range of motion: the 3-axis CNC milling machine can only move along three axes (X, Y, and Z), which limits its ability to machine complex parts with features on multiple sides.

2. Limited ability to machine undercuts or features on multiple sides of a part: the 3-axis CNC milling machine can only machine features that are accessible from above, which limits its ability to machine undercuts or features on multiple sides of a part.

3. Requires skilled operators: The 3-axis CNC milling machine requires skilled operators who have experience with the programming, setup, and operation of the machine. This can lead to higher labor costs and long setup times.

While 3-axis CNC machining is a highly efficient and versatile technology, it does have some limitations that must be taken into account when selecting a machining method for a particular application. For more complex parts, 4 or 5-axis CNC machining may be a better option.

Differences between 3-axis milling, 4-axis milling, and 5-axis milling

The main differences between 3-axis, 4-axis, and 5-axis milling are the number of axes that the cutting tool can move along, the complexity of the parts that can be produced, and the level of precision that can be achieved. Here are the key differences between these three types of milling:

1. 3-axis milling: In 3-axis milling, the cutting tool can move along the X, Y, and Z axes. This is the most basic type of milling and is suitable for producing simple, flat parts with relatively straight edges. However, it is limited in its ability to produce complex shapes and curves.

2. 4-axis milling: In 4-axis milling, the cutting tool can move along the X, Y, and Z axes as well as an additional rotational axis. This allows for more complex parts to be produced, such as parts with curved surfaces or angled features. 4-axis milling is commonly used in industries such as aerospace and automotive, where parts with complex shapes and angles are required.

3. 5-axis milling: In 5-axis milling, the cutting tool can move along the X, Y, and Z axes as well as two additional rotational axes. This allows for even greater complexity in the parts that can be produced, including parts with highly contoured surfaces and intricate details. 5-axis milling is commonly used in industries such as medical, dental, and jewelry, where highly detailed and precise parts are required.

Generally speaking, the key advantages of 4-axis and 5-axis milling over 3-axis milling are the ability to produce more complex shapes, achieve higher levels of precision, and reduce the need for multiple setups and operations. However, these advantages also come with increased costs, as 4-axis and 5-axis milling machines are typically more expensive than 3-axis CNC milling machines and require more Offersskilled operators to run.

How to Find a High Precision 3-Axis CNC Machining Services Provider

First, identify your specific needs. Before you begin your search, it’s important to identify your specific requirements for your parts or products. Determine the material, tolerances, and surface finish requirements for your parts.

Once you have defined your needs, you should start looking for a high-precision 3-axis CNC machining service provider. Capable Machining is your reliable choice. They specialize in providing the highest quality CNC machining services to meet the needs of clients worldwide.

1. Precision: Capable Machining is known for providing precision machining services using advanced 3-axis CNC milling machines. This ensures that every component produced meets strict quality standards and tolerances.

2. Versatility: Capable Machining has the ability to machine a wide range of materials, including metals, plastics, and composites. This allows them to provide machining services for a variety of industries, such as aerospace, medical, and automotive.

3. Efficiency: Capable Machining utilizes advanced CNC machining technology and software to optimize production processes and reduce lead times. This ensures that customers receive their components in a timely and cost-effective manner, without compromising on quality.

Final Thoughts

In conclusion, 3-axis CNC machining is a highly efficient and versatile manufacturing technology that offers several advantages over traditional machining methods. It is widely used in various industries, including automotive, aerospace, medical, and electronics, among others.

One of the key advantages of 3-axis CNC machining is its high accuracy and repeatability, which ensures consistent and reliable production runs. It also offers high production speed and the ability to machine complex shapes with ease, making it ideal for a wide range of applications.

However, there are also some limitations to 3-axis CNC machining, including its limited range of motion and ability to machine undercuts or features on multiple sides of a part. It also requires skilled operators who have experience with the programming, setup, and operation of the machines.

Overall, 3-axis CNC machining is a valuable technology that has transformed the manufacturing industry. By understanding its advantages and limitations, manufacturers can determine when and where to best apply this technology in their operations.

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Name *

Email *

Add Comment *

Save my name, email, and website in this browser for the next time I comment.

I accept the Privacy Policy *

Post Comment

Let's Start A New Project Today

Preventive Maintenance Insights

Keep your lathe turning at peak performance. Watch this video to make downtime a thing of the past.

Product Detail

Our VTM-100 3-axis vertical turning center combines the benefits of a vertical lathe with those of a machining center. The 50-taper 36-tool magazine enables this machine to offer both turning and milling operations on a single platform. It is the ideal machine for efficient low-volume parts production, including valve bodies and work that requires heavy milling. The box-way construction and wide, angular slideways on each axis provide high rigidity for accurate machining. A vertical axis counterbalance assures smooth, stable feed at all speeds. The headstock is fixed to the base, minimizing the influence of thermal changes and vibration on cutting accuracy. In addition, the VTM-100 is available with a wide range of standard accessories, including a spindle orientation function.

Learn more about Lathes .

Highlighted Specs

Perfect automation pairings.

This machine tool is compatible with the following automation solutions for increased production, accuracy, and efficiency across your operations.

Bar Feeders →

Automatic Pallet Changers →

Flexible Manufacturing Systems →

Gantry Loaders →

Industrial & Integrated Robotics →

Armroid →

Cobots →

Standroid →

Related Products

What can we do to help?

Your local Okuma distributor will be happy to give you a call or visit your facility to discuss your machine tool needs.

Plastic 3D Printing Service

Fused Deposition Modeling

HP Multi Jet Fusion

Selective Laser Sintering

Stereolithography

Production Photopolymers

Nexa3D LSPc

Direct Metal Laser Sintering

Metal Binder Jetting

Vapor Smoothing 3D Prints

CNC Machining

CNC Milling

CNC Turning

Wire EDM Machining

Medical CNC

CNC Routing

Sheet Metal Fabrication

Sheet Cutting

Laser Cutting

Waterjet Cutting

Plasma Cutting

Tube Bending

Laser Tube Cutting

Laser Engraving

Custom Die Cutting

Plastic Injection Molding

Quick-Turn Molding

Prototype Molding

Bridge Molding

Production Molding

Overmolding

Insert Molding

Urethane and Silicone Casting

Plastic Extrusion

HDPE Injection Molding

Injection Molded Surface Finishes

Custom Plastic Fabrication

Micro Molding

Metal Injection Molding

Die Casting

Metal Stamping

Metal Extrusion

Custom Hydroforming

Assembly Services

Rapid Prototyping

High-Volume Production

Precision Grinding

Surface Grinding

Powder Coating

Aerospace and Defense

Consumer Products

Design Agencies

Electronics and Semiconductors

Hardware Startups

Medical and Dental

Supply Chain and Purchasing

All Technical Guides

Design Guides

eBooks Library

3D Printing Articles

Injection Molding Articles

Machining Articles

Sheet Cutting Articles

Xometry Production Guide

CAD Add-ins

Manufacturing Standards

Standard Sheet Thicknesses

Standard Tube and Pipe Sizes

Standard Threads

Standard Inserts

ITAR and Certifications

Case Studies

Supplier Community

Release Notes

Call: +1-800-983-1959

Email: [email protected]

Discover Xometry Teamspace

Meet An Account Rep

eProcurement Integrations

Bulk Upload for Production Quotes

Onboard Xometry As Your Vendor

How to Use the Xometry Instant Quoting Engine®

Test Drive Xometry

Tool Library and Tool Detail Pages

Part Revisions & Same-Suppliers for Repeat Orders

Xometry's Privacy and Security

Xometry’s Quality Assurance

Xometry’s Supplier Network

Xometry's Machine Learning

3-Axis vs. 5-Axis CNC: Advantages and Disadvantages

Learn more about these two CNC machining processes and how they can each be used.

Over time, CNC machines have gained popularity across most manufacturing sectors. These devices automate manufacturing processes such as: cutting, drilling, milling, and turning, and they do it all using computer numerical control (CNC) technology. CNC machines allow for the highly accurate and precise production of intricate designs and parts. There are several kinds of CNC machines, but most fall under the 3-axis or 5-axis categories. These two differ in their axes of motion capabilities. This article will discuss the advantages and disadvantages of 3-axis and 5-axis CNC machines.

.css-2xf3ee{font-size:0.6em;margin-left:-2em;position:absolute;color:#22445F;} .css-14nvrlq{display:inline-block;line-height:1;height:1em;background-color:currentColor;-webkit-mask:url(https://assets.xometry.com/fontawesome-pro/v6/svgs/light/link.svg) no-repeat center/contain content-box;mask:url(https://assets.xometry.com/fontawesome-pro/v6/svgs/light/link.svg) no-repeat center/contain content-box;-webkit-mask:url(https://assets.xometry.com/fontawesome-pro/v6/svgs/light/link.svg) no-repeat center/contain content-box;aspect-ratio:640/512;vertical-align:-15%;}.css-14nvrlq:before{content:"";} What Is CNC?

What is a 3-axis cnc.

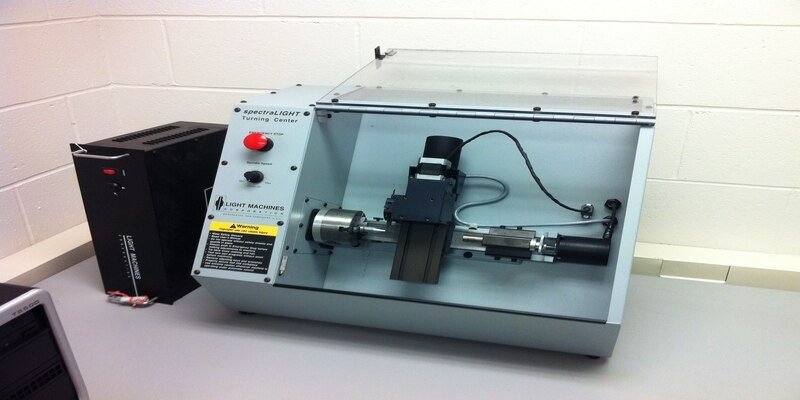

A 3-axis CNC machine is one that performs machining operations by moving its tool or the part along the X, Y, and Z axes. The cutting tool can be moved anywhere along the horizontal (X-Y) plane and cut into parts to specified depths (Z-axis motion). Figure 1 is an example of a 3-axis CNC machine:

For more information, see our guide on the Types of CNC Machines .

3-axis CNC machine.

Image Credit: Shutterstock.com/Pixel B

What Can a 3-Axis CNC Do?

A typical 3-axis CNC machine is capable of carrying out a variety of machining tasks, including: cutting, drilling, and milling. Others are designed as CNC lathes. However, in terms of part complexity, the constraint of those three axes means the machine has some distinct limitations. The best 3-axis machines are used to produce parts with straightforward geometries and minimal design or detail requirements. 2D and 2.5D parts are the best targets for 3-axis CNC machines.

What Are the 3-Axis CNC Examples?

Examples of 3-axis CNC devices are:

- CNC milling machines

- CNC machine tool centers

These machines are frequently employed in sectors like automotive, aerospace, and electronics.

What Are the Advantages of 3-Axis CNC?

The advantages of 3-axis CNC machines are listed below:

- Cost-Effective: 3-axis CNC machines are more reasonably priced than 5-axis machines.

- Easy to Operate: 3-axis CNC machines require minimal training and are simple to use. They are appropriate for small to medium-sized businesses because they are also simple to program.

- Low Maintenance: Compared to 5-axis CNC machines, 3-axis CNC machines have fewer moving parts, making them simpler to maintain and less prone to wear and tear.

- High Accuracy: A variety of applications can benefit from the accurate and precise parts built on a 3-axis CNC machine.

What Are the Disadvantages of 3-Axis CNC?

The disadvantages of 3-axis CNC machines are:

- Limited Capability: Since there’s no way to automatically rotate the workpiece, 3-axis machines can only attack from certain angles. They work best for making parts with simple geometries.

- Limited Efficiency: These are less efficient than 5-axis CNC machines because they require multiple setups to produce complex parts.

Does the 3-Axis CNC Not Capable of Creating 3D Objects?

While 3-axis CNC machines can create 3D objects, there are some restrictions. 3-axis CNC machines can produce 3D parts with clear and simple geometries but not those with complex geometries and finely detailed designs.

What Is a 5-Axis CNC?

A 5-axis CNC machine performs machining operations along five axes of motion. It can move along the three linear axes (X, Y, and Z) and rotate around the other two axes (A and B). This expanded range of motion enables the machine to generate intricate geometries. Figure 2 is an example of a 5-axis CNC machine:

5-axis CNC machine.

What Can a 5-Axis CNC Do?

A 5-axis CNC can create geometries that demand multiple angles and contours. It can move the cutting tool along five axes, leading to smoother surfaces and more precise parts. A 5-axis CNC machine can also perform continuous milling, which enables the cutting tool to follow the material's curvature and produce fewer marks and steps.

A 5-axis CNC machine can be used to create parts such as: impellers, turbine blades, molds, and aerospace components. For instance, it is used in the aerospace industry to create intricate shapes for aircraft engine components. 5-axis capability is also important for medical implants and prosthetics. For more information, see our guide on Everything You Need to Know About CNC Milling .

What Are the 5 Axis CNC Examples?

Some examples of 5-axis CNC machines include:

- Continuous 5-axis CNC machines

- 5-Axis CNC milling machines

- 5-Axis CNC routers

What Are the Advantages of 5-Axis CNC?

Listed below are the advantages of 5-axis CNC machines:

- Increased Efficiency: 5-axis machines can speed up production and improve efficiency. They can produce complex shapes and perform continuous milling operations.

- Improved Accuracy: They can create smoother surfaces and more accurate parts because they enable the cutting tool to move along five axes.

- Reduced Tool Changes: Complex geometries are possible thanks to continuous milling operations. That also translates into fewer tool changes. This continuous milling reduces the need for manual intervention and saves time.

- Versatility: 5-axis devices can produce a wide variety of parts and geometries.

What Are the Disadvantages of 5-Axis CNC?

Listed below are the disadvantages of 5-axis CNC machines:

- Cost: 5-axis CNC machines are more expensive than 3-axis CNC machines, making them harder for smaller businesses to afford.

- Training: Due to their complexity, they require more specialized training and expertise to operate and maintain.

- Maintenance: Regular maintenance is necessary to keep these complex machines running smoothly and to prevent breakdowns.

Does 5-Axis CNC Have No Limitations To Angle?

A 5-axis CNC machine can mill materials at nearly any angle, but it does have some restrictions. The length of the cutting tool, the nature of the material being milled, and the reach of the machine itself all affect the possible angles and dimensions. Additionally, the cutting tool becomes less stable at more extreme angles, which may have an impact on precision.

What Is the Difference Between 3-Axis and 5-Axis CNC?

A 3-axis CNC and 5-axis CNC differ in their ability to orient and move the cutting tool along multiple axes. A 3-axis CNC machine is capable of moving its cutting tool along the X, Y, and Z axes. A 5-axis machine, on the other hand, can move the cutting tool along the X, Y, Z, A, and B axes.

The machine’s price is another difference between the two. Of the two, the 3-axis version is far cheaper to buy, program, and operate. The cost per part is thus often lower as well.

Another critical differentiating factor is the ease with which you can create and manipulate complex shapes. Even in complex geometries, deep cuts are possible with 5-axis machines. You can work on all sides of your workpiece without manually rotating it, thus improving productivity. A 3-axis machine, on the other hand, needs numerous adjustments to help the machine cut complex geometry.

How Much Does 5-Axis CNC Cost Compare to 3-Axis CNC?

Prices for 3-axis CNC devices range from $25,000 to $50,000 while 5-axis go from $80,000 to over $500,000. The costs vary depending on whether they are used for entry-level or production-level work.

How Are 3-Axis CNC and 5-Axis CNC Programmed?

Programming for both 3- and 5-axis CNC work is done manually by professionals. However, programming 3-axis machines is easier than programming 5-axis machines, so the latter will usually warrant a higher-paid programmer. For more information, see our guide on What is CNC Programming?

Is the 3-Axis CNC a Good Starter Investment Than the 5-Axis CNC?

Yes, a 3-axis CNC is a better starter investment than a 5-axis CNC. It is more affordable in terms of purchase, development, and upkeep costs.

Do CNC Machines Use a Lot of Electricity?

Yes, CNC machines draw quite a bit of power. A 20-hp conventional CNC machine with a 7 kw/hr rating can run a monthly power bill of around $1,400. However, some CNC machines are more energy-efficient than others.

Xometry provides a wide range of manufacturing capabilities, including CNC machining and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote .

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

- [email protected]

- 0086 13287753168

- United States (US) dollar Euro Pound sterling

- ATC CNC Router

- Smart CNC Router

- Mini CNC Router

- 3 Axis CNC Router

- 4 Axis CNC Router

- 5 Axis CNC Router

- Rotary Axis CNC Router